What is shell cordovan leather?

There are numerous types of expensive leather, shell cordovan leather is one of them. And you may be wondering what is shell cordovan leather? How is shell cordovan made? What makes it so expensive? Well in this article we are about to answer all your questions.

It is also known as horse butt leather as it comes from the butt of horse. Though, originally it came from goat not horse.

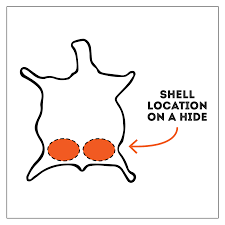

The shell cordovan, or simply cordovan leather, comes from a specific part of the horse called the shell. The shell is located on the hindquarter part of the horse’s butt and is a membrane between two layers of the epidermis. This area begins approximately 24 inches from the tail and extends 24 to 28 inches on either side of the horse.

The cordovan leather is the kind of split leather found beneath the hide on the butt (shell portion) of a horse. The top grain layer is horizontally split from the leather.

Cordovan leather has very dense pores, which are hardly visible to the naked eye. This characteristic makes cordovan leather exceptionally smooth, durable, and highly water-resistant. These qualities make it ideal for crafting a variety of items such as shoes, wallets, belts, bags, watch straps, and other specialty items.

History of cordovan leather

Centuries ago, the origins of shell cordovan can be traced back to Cordoba, Spain. It derived its name “cordovan” from this very place, as the term itself signifies “from Cordoba.” Shell cordovan denotes leather sourced from Cordoba, coveted in the Middle Ages for its unparalleled quality and smooth texture.

The mass production of cordovan leather started in the United States by the Horween Leather Company in Chicago, founded in 1905. They developed the process for producing high-quality cordovan leather, eventually making it popular for crafting various leather accessories.

Despite fluctuations in demand in the market, shell cordovan has secured its position to date and is still one of the first choices for luxury leather goods makers around the world.

What makes shell cordovan leather expensive?

1.| Limited availability

The production of cordovan leather is relatively limited due to the labor-intensive work involved and the availability of special raw material.

2.| Unique appearance

The beautifully unique appearance of cordovan leather is also the reason why it commands a high price due to its high demand. It possesses a smooth, glossy surface that develops a slight luster during finishing. It also ages well, developing a beautiful patina.

3.| Craftsmanship

Not anyone can work with cordovan leather, as it requires skilled professionals due to its unique characteristics. These artisans often charge high prices for their expertise, which further increases the expense of cordovan.

4.| Exclusiveness

Shell is a small portion of horse hide, yielding a limited amount of cordovan leather. This scarcity contributes to its reduced availability and elevated price.

How is shell cordovan made?

The process of making shell cordovan leather is intricate and time-consuming. Here’s a simplified overview of the steps involved:

1.| Selection of hides

The first step involves the selection of the best quality horsehide, and the hindquarter, where the shell is located, is inspected properly.

2.| Preparation of hide

The preparation involves various processes like cleaning, soaking and liming of hide to remove hair and other impurities.

3.| Cutting of shell portion

This step is unique in cordovan leather production. A skilled artisan cuts specific parts of the hide so that the shell part is separated, and other parts of the hide are also saved for other uses. This is done because in cordovan leather making, herbal or vegetable tanning is often involved, which is not done on other portions of horsehide.

4.| Tanning

Here comes the most crucial step in which rawhide is turned to leather. The oval shell portion is subjected to tanning process using vegetable tannin. This method of tanning is comparatively slow and vegetable leather obtained by this method of tanning is more expensive. You can read more about tanning here.

5.| Shaving

Unlike other leathers, in which splitting follows the tanning process, cordovan leather undergoes a shaving process to precisely shave off any uneven surfaces. This ensures an even smoother surface without defects.

6.| Dyeing

After shaving, cordovan leather undergoes a dyeing process to achieve the desired color. Multiple layers of color are applied to achieve deeper shades.

7.| Finishing

Once the hide is dyed, it undergoes finishing, which involves polishing, buffing, embossing (if required), and glazing to achieve a smooth, shiny surface.

8.| Quality check

The final step, common in the manufacturing of any type of leather, is the quality check. This stage involves various inspection checks to ensure that the finished product conforms to industry standards. Leather is inspected for any defects or inconsistencies, ensuring that only the highest quality pieces are approved for sale.

Conclusion

Well, I hope you’ve found answers to all your questions, such as what is shell cordovan leather and how it’s made. However, a common question remains: Is shell cordovan leather really worth the price? In my opinion, the answer is definitely yes. Considering all its qualities and the meticulous craftsmanship that goes into making it, shell cordovan is worth the extra investment. No other leather can quite match the luxurious feel of fine cordovan.

Related articles: can you dye leather that is already dyed?

which is better PU leather or faux leather?